by Fred Eaton

Summary:

If you are racing your Commando or just like everything safety wired like I do, I have found a good way to safety wire the brake rotors.

This article will cover the procedure I follow to safety wire brake rotors.

Procedure:

The Commando rotor is normally held on with five 5/16 x 24 studs (06-1960), five lock washers (60-2418) and five nuts (14-0302). The reason to use a stud instead of a bolt is that "in theory", you can remove the rotor without removing the studs and by not removing the studs, you lessen the possibility of damaging the threads in the aluminum hub. I say "in theory" since a lot of times the stud screws out with the nut attached, instead of the nut coming off the stud. Also, you don't remove the brake rotor that often, and if you are careful, you will not damage the threads in the hub. Therefore I like to use stainless allen head bolts (52-130202) to mount the rotors.

Drilling the five nuts and safety wiring them is a solution to safety wiring your rotor, but I find that using the stainless allen bolts works much better that drilling the nuts. I replace the studs, lock washers and nuts with stainless allen bolts and stainless washers (52-330301).

When I drill the bolts, I drill four holes where two holes are opposite each other and the holes are just above the base of the hex recess. I use a 1/16 drill (70-600031) and .032" stainless safety wire (70-600030). I drill two sets of holes so I will always have a set of holes close to where I want to string the safety wire. The wire will go into one hole and out the hole opposite it. I made a jig to hold the head of the allen bolt and mark where I want to drill, but you can use a center punch to do the same. I do not drill all the way through the head of the bolt, since I found I broke too many drills trying to drill straight through. I drill each hole separately.

It is a pain to drill stainless, but you should be able to drill all five bolts with around two drills. I can sometimes drill three to four bolts with the same drill and sometimes it will take me three drills to get one bolt drilled. The nice thing about stainless fasteners drilled for safety wiring, is you only have to do it once and your pre-ride inspection is simply seeing that the safety wire is taut.

If you don't want to go through the frustration of drilling your bolts, we do provide a rotor mounting kit (06-1960/SSK) that includes the five stainless allen bolts drilled and five stainless washers. We charge 1/2 hour of shop time to drill the five bolts and cover the cost of the drills.

After you have drilled the five bolts, torque them to 20 to 25 ft. lb. in a diagonal pattern. I normally apply an anti-seize lubricant to any stainless bolt, especially when that bolt is safety wired.

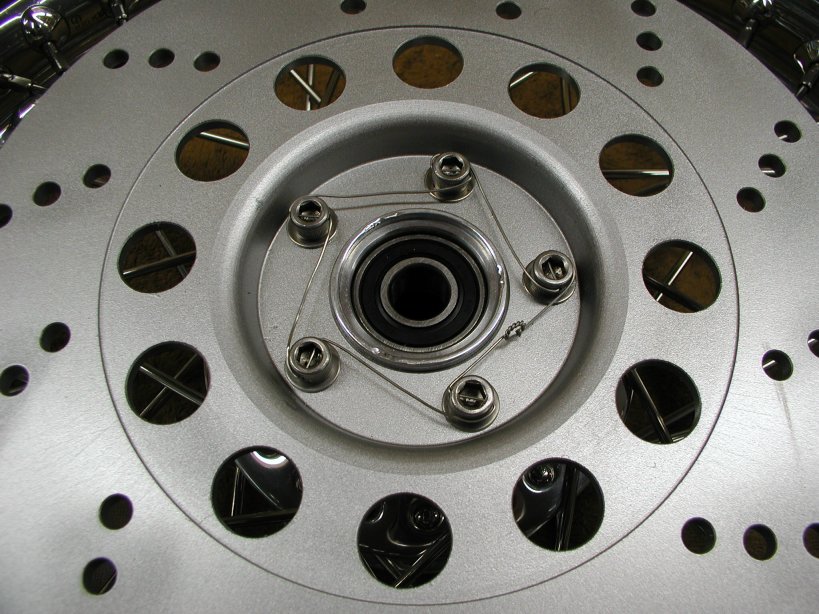

Thread the safety wire through the bolts trying to have the wire as straight as possible like the above picture. Twist the ends together; making sure that the wire is very taut between each bolt. With the wire going through the head of each bolt, that bolt can not unscrew. If you have to go into the head on a bolt from the side, make sure the wire is tightening the bolt like the top bolts in the above picture.

The following is a list of parts mentioned in this article and current prices as of 02/12/21.

- 06-1960 -- Stud, 5/16 x 24, $2.90.

- 60-2418 -- Washer, 5/16, Lock, Plated, $0.16.

- 14-0302 -- Hex Nut, 5/16 x 24, Plated, $0.24.

- 52-130202 -- Allen Bolt, 5/16 x 24, 1", Stainless Steel, $2.24.

- 52-330301 -- Flat Washer, 5/16, Stainless, $0.20.

- 70-600031 -- Twist Drill, 1/16", Steel, Quad-Cut, $3.11.

- 70-600030 -- Stainless Safety Wire, .032", 1 Lb., App. 360ft, $25.95.

This page was written and designed by F. H. Eaton & Associates if you have any questions or comments please contact us at info@fheaton.com